machiningTEQ

Technology & Solutions - MachiningTEQ

MSG develops pioneering automotive solutions for the mobility of tomorrow. With our pioneering innovations and precise mechatronic details, we create the decisive difference that redefines the future of the automotive industry.

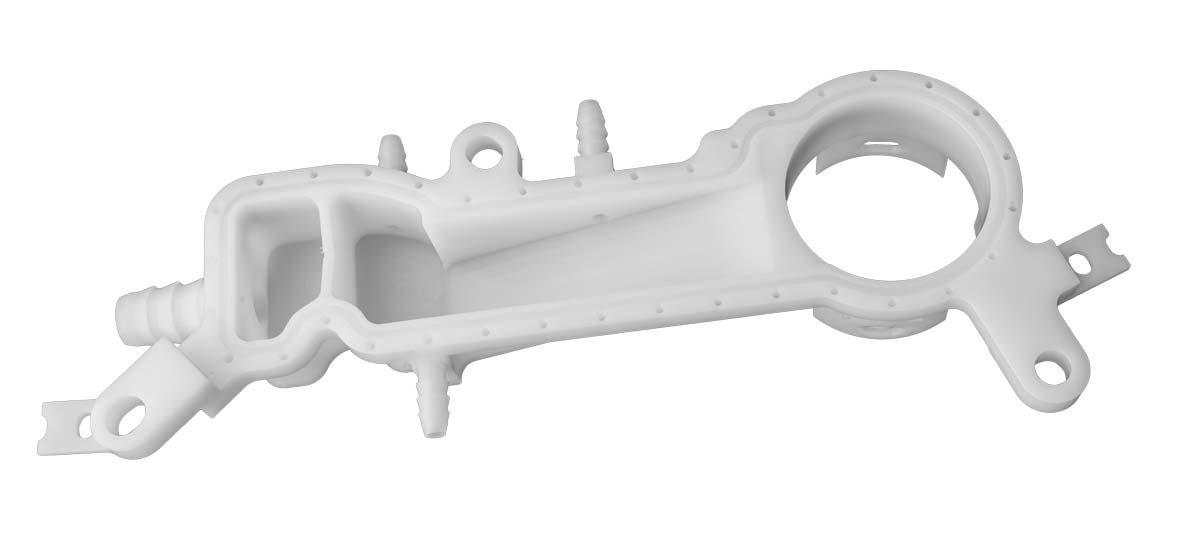

Turning

Individual solutions for small to large series with maximum precision

- Complex turned parts

- 3-turret turning and milling

- Powered tools

- Synchronous turning

- Bar loader up to 3 m

Position tolerance

0

µm

Key facts

Anodizing with pre-mounted fit

Key facts

Machine deburring of milling contours

Key facts

Individual saw threads

Key facts

Thin-walled knurl production

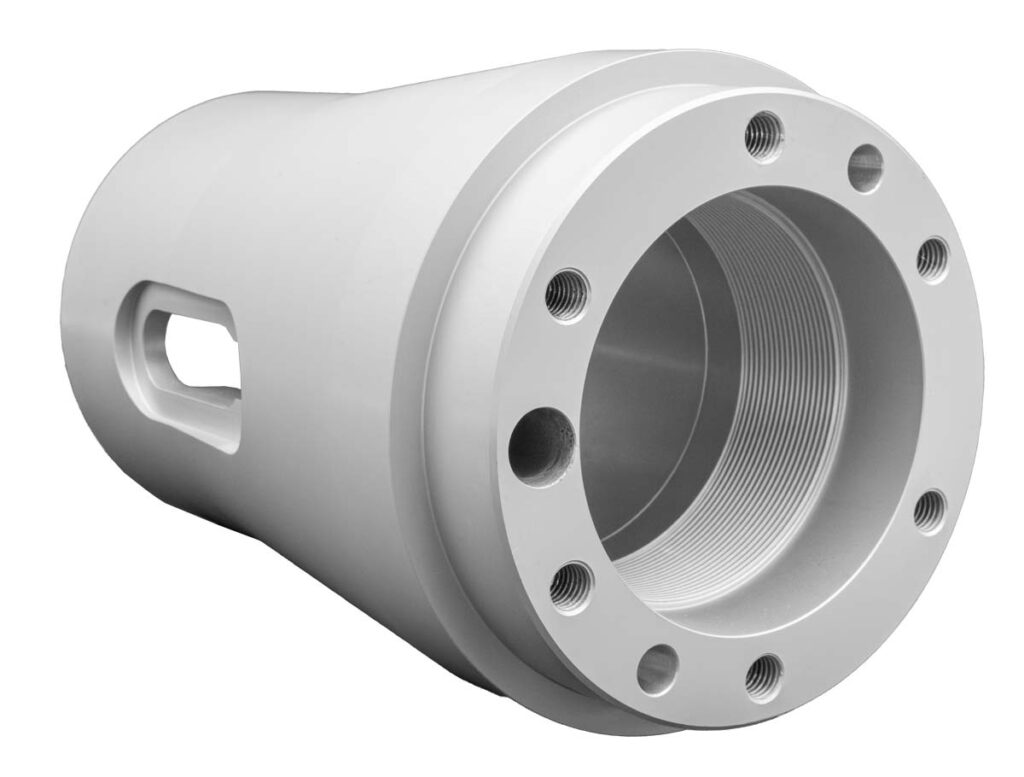

Milling

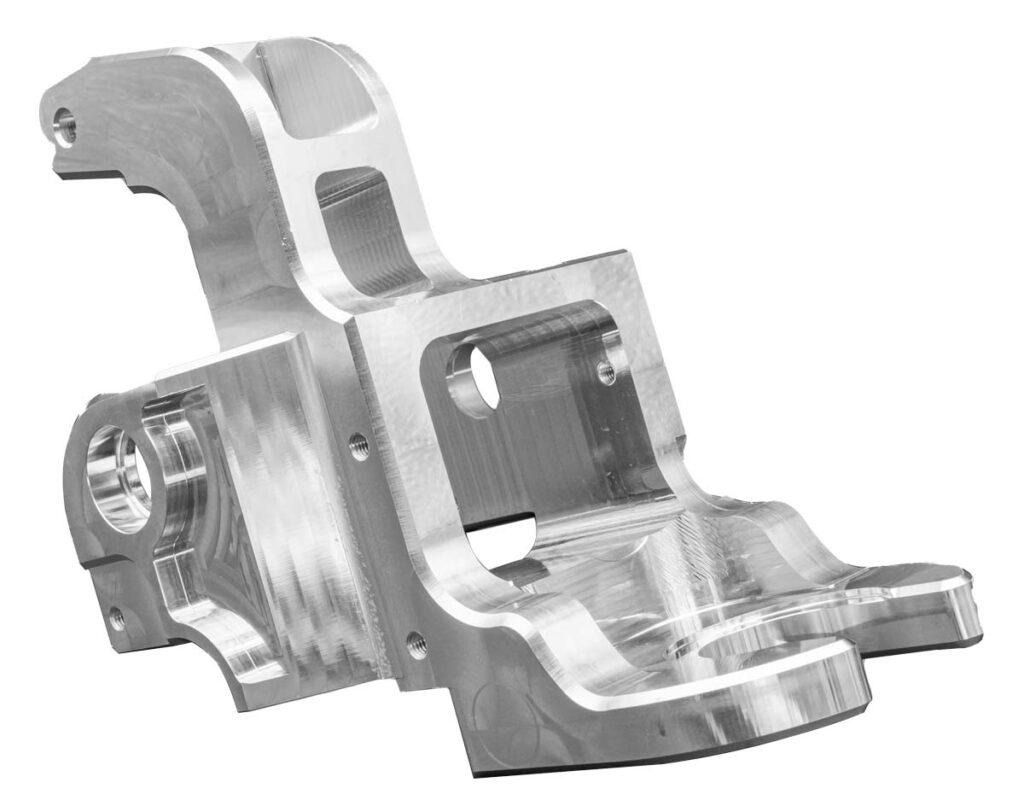

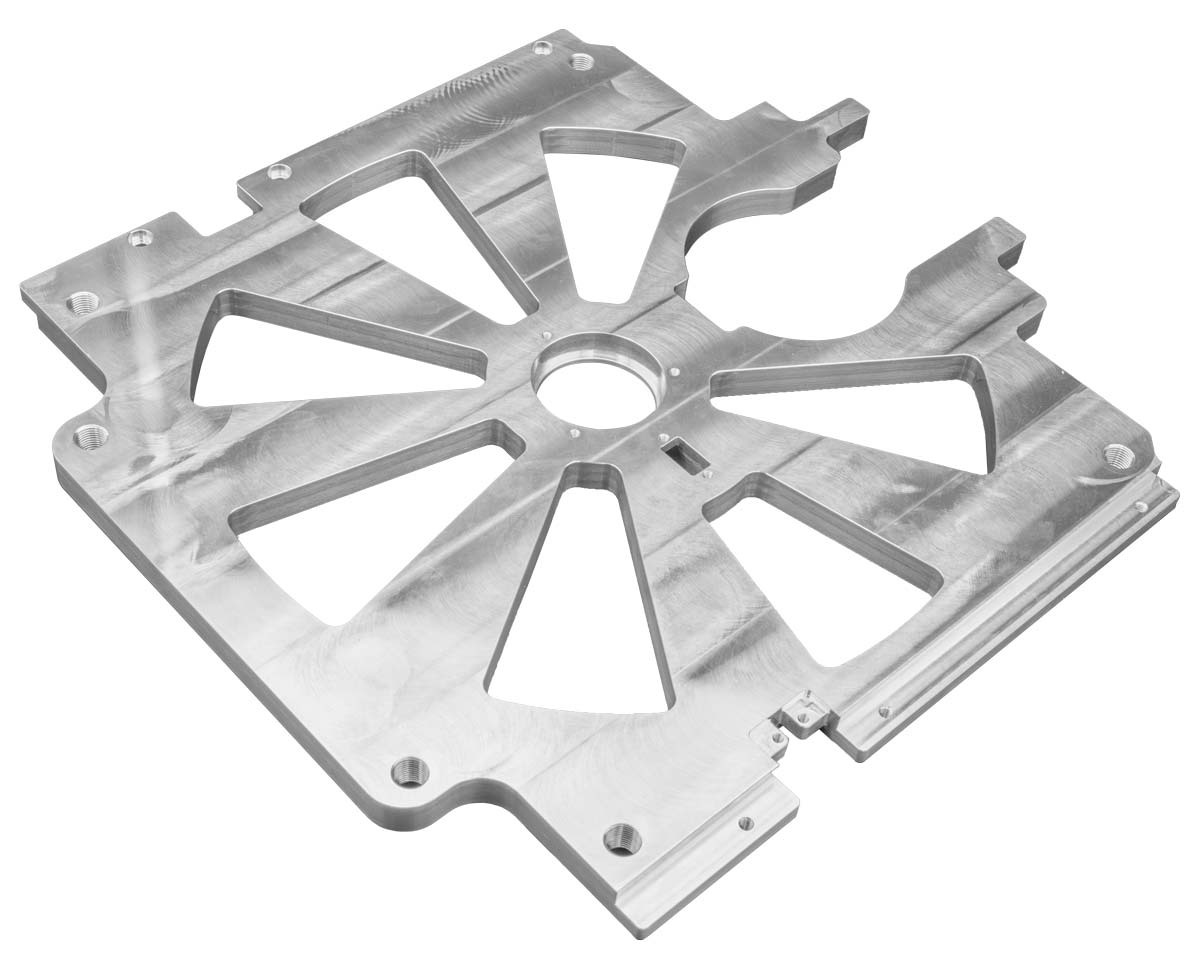

Customized solutions for prototypes and small series of the highest precision

- Complex milled parts

- 5-axis simultaneous machining

- Freeform surfaces

- Surface reconstruction and 3D coordinate measuring machine with scanning function

Accuracy

0

µm

Key facts

Cylindricity of bores 50 µm

Key facts

High-precision 5-axis machining

Key facts

Complex simultaneous milling according to 3D model

Key facts

Manufacturing using a clamping fixture with mirrored contours

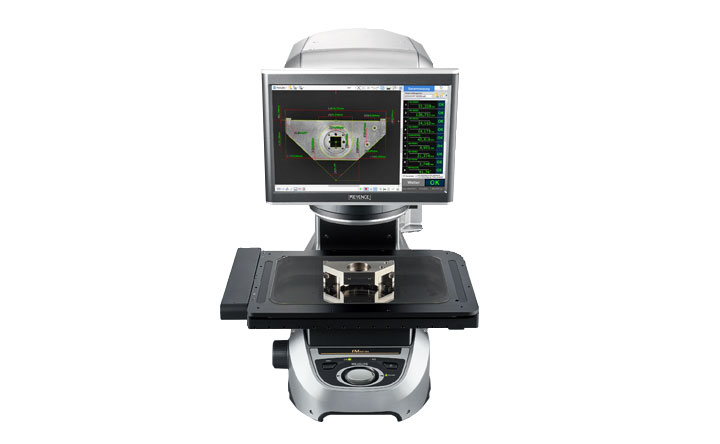

Measuring technology

Zero-Defect: Measurement technology in air-conditioned production and test rooms

- State of the art measuring equipment

- 3D coordinate measuring technology with scanning function

- Highest quality through cleanliness and constant production conditions

Machinery

We manufacture prototypes, small batches and medium-sized series - precisely and efficiently. With 3-turret turning/milling, driven tools, synchronous turning and a bar loading magazine up to 3 meters, we offer solutions for complex turned parts of the highest quality.

Got Questions?